Views: 0 Author: Site Editor Publish Time: 2025-09-10 Origin: Site

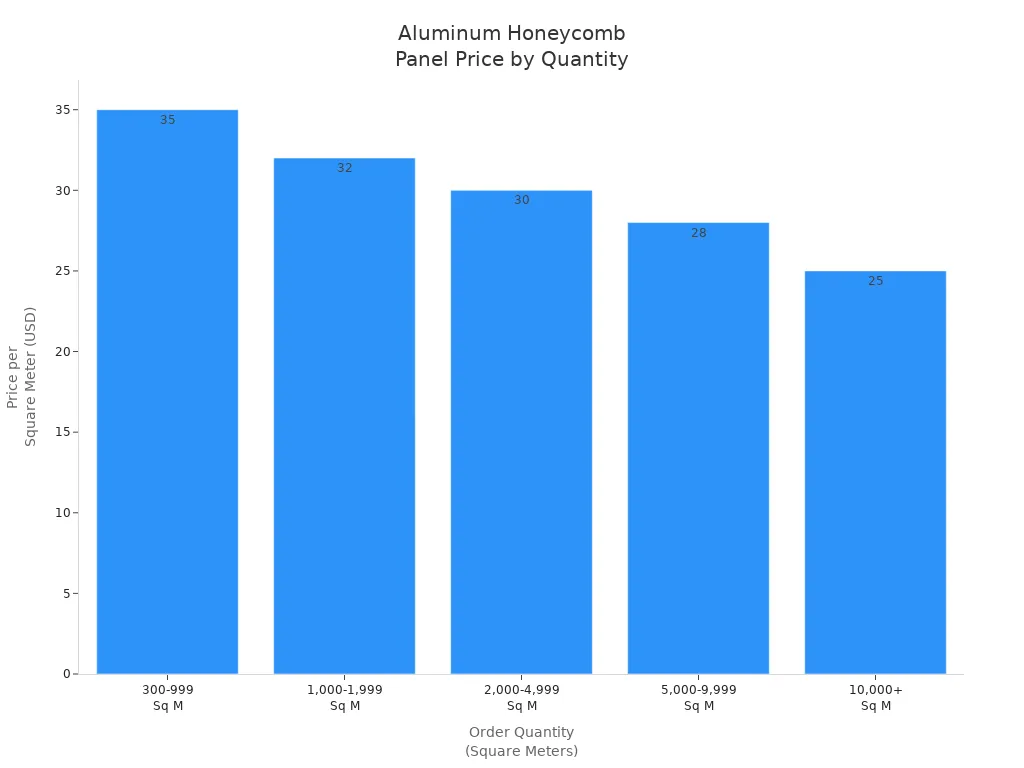

When you look for aluminum honeycomb panels in the standard 4x8 size from Chinese suppliers, you see prices from $25 to $35 per square meter, depending on order volume.

| Quantity Range | Price per Square Meter (USD) |

|---|---|

| 300-999 Square Meters | $35.00 |

| 1,000-1,999 Square Meters | $32.00 |

| 2,000-4,999 Square Meters | $30.00 |

| 5,000-9,999 Square Meters | $28.00 |

| 10,000+ Square Meters | $25.00 |

You notice that thickness, surface finish, core material, and order volume all affect cost. Zhejiang Kangzhan New Materials Co. Ltd. offers panels with strong, lightweight construction and excellent corrosion resistance. You benefit from these panels in architecture, transportation, and industrial settings. Choosing a reliable manufacturer ensures you get high quality and the best value.

Aluminum honeycomb panels in the 4x8 size range from $25 to $35 per square meter, with lower prices for larger orders.

Thickness, surface finish, and order volume significantly affect the cost of aluminum honeycomb panels.

Choosing a reliable manufacturer ensures high quality and value; check for certifications and customer reviews.

Bulk orders can lead to substantial savings, with prices dropping as order size increases.

Select the right thickness for your project; thicker panels offer more strength and rigidity for heavy-duty applications.

Different surface finishes provide various benefits; PVDF and powder coatings are ideal for outdoor use.

Always ask for samples before placing a large order to verify quality and suitability for your needs.

Use online platforms like Alibaba and Made-in-China.com to compare suppliers and find the best deals.

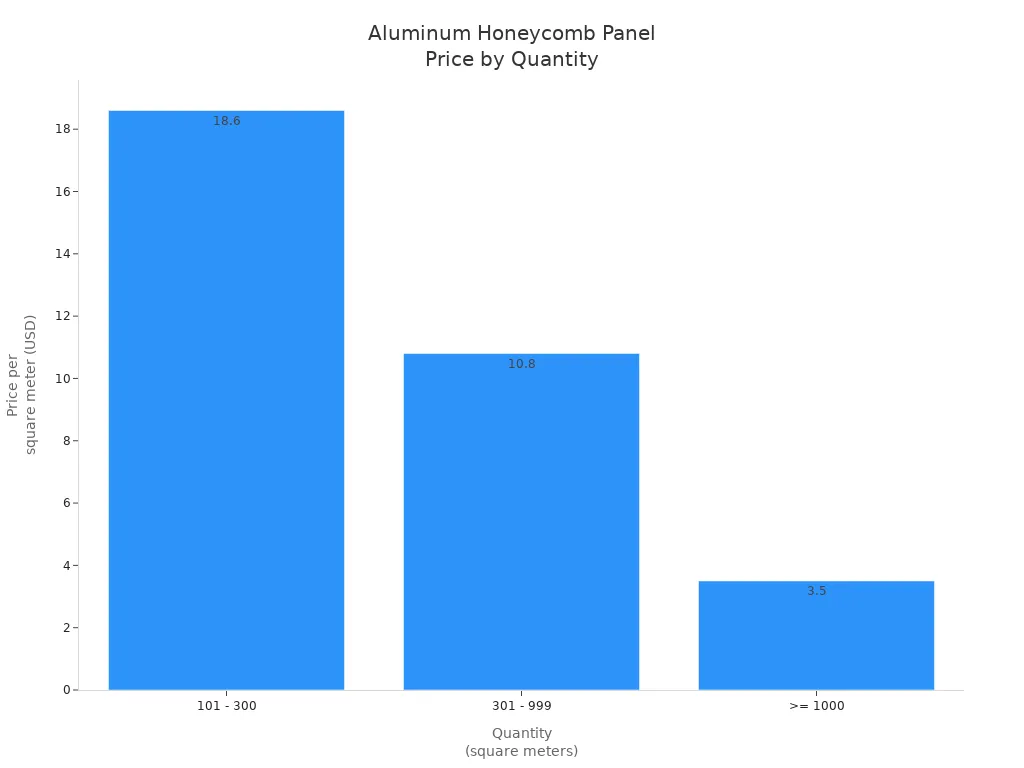

When you compare prices for aluminum honeycomb panels in the standard 4x8 size, you see a wide range. The cost depends on how many panels you order. If you buy between 101 and 300 square meters, you pay about $18.60 per square meter. For orders from 301 to 999 square meters, the price drops to $10.80 per square meter. Large orders of 1,000 square meters or more can bring the price down to $3.50 per square meter. This pricing structure helps you save money when you buy in bulk.

| Quantity (square meters) | Price per square meter (USD) |

|---|---|

| 101 - 300 | $18.60 |

| 301 - 999 | $10.80 |

| ≥ 1000 | $3.50 |

You notice that the price per sheet also changes with thickness, finish, and order volume. Zhejiang Kangzhan New Materials Co. Ltd. offers competitive rates for large projects, making it easier for you to plan your budget.

You can choose from many thicknesses and sizes when you select aluminum honeycomb panels. Most suppliers offer thicknesses from 4 mm up to 200 mm. The most common sizes are 1220 x 2440 mm, which matches the standard 4x8 feet panel. You also find options for custom sizes if your project needs something special. Thicker panels provide more strength and rigidity, which is important for heavy-duty applications.

| Thickness (mm) | Aluminum Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|---|

| 7, 9, 12, 15, 20, 25, 30 | 0.40 - 1.0 | 1220, 1250, 1570 (Max) | 2440 (customizable) |

| Total Thickness (mm) | Standard Thickness (mm) | Standard Size (mm) |

|---|---|---|

| 6 - 200 | 6, 15, 20, 25, 30, 35, 40 | 1220 x 2440 (customizable) |

| Minimum Core Thickness (mm) | Standard Dimension (mm) | Cell Size (mm) |

|---|---|---|

| 3 | 1220 x 2440 | 3.2 - 25 |

You get flexibility with these choices. If you need panels for walls, ceilings, or vehicle interiors, you can pick the right thickness and size for your project.

Surface finishes play a big role in the price and performance of aluminum honeycomb panels. You can select from several finishes, each with its own benefits. PVDF coatings give you strong weather and chemical resistance, which is great for building exteriors and vehicle casings. Anodized coatings add color and extra hardness, making them popular for interior decoration and furniture. Powder coatings offer durability and are environmentally friendly, while polyester PE coatings provide many color choices for indoor use. Epoxy coatings help with bonding panels to other materials.

| Surface Finish Type | Description | Common Applications |

|---|---|---|

| Fluorocarbon PVDF coating | High-performance anti-corrosion coating with excellent weather and chemical resistance. | Building exteriors, vehicle casings |

| Anodized coating | Provides good corrosion resistance and hardness; can be dyed for colorful effects. | Interior decoration, furniture manufacturing |

| Powder coating | Environmentally friendly, strong coating with excellent weather and abrasion resistance. | Outdoor furniture, fences, doors, windows |

| Polyester PE coating | Available in many colors, cheaper option for indoor applications. | Indoor wall partitions, billboards |

| Epoxy coating | Enhances adhesion of the substrate to other materials, preventing bonded materials from falling off. | Bonding aluminum honeycomb panels to other materials |

Tip: If you want a panel that lasts longer outdoors, choose a PVDF or powder-coated finish. For indoor projects, polyester PE or anodized finishes work well and help you save on costs.

Surface finishes also affect the look and feel of your panels. You can pick finishes that add texture, color, and style to your space. Many finishes use recyclable materials, which supports eco-friendly building practices.

When you plan a large project, you want to know how much you can save by ordering in bulk. Chinese manufacturers offer significant discounts when you buy more aluminum honeycomb panels. The price per square meter drops as your order size increases. You also need to meet minimum order quantities to access these lower prices.

Here is a table that shows typical bulk pricing and minimum order requirements:

| Minimum Order Quantity | Price Range (per sqm) |

|---|---|

| 200 sqm | US$10.00 - 40.00 |

You see that the more you order, the less you pay for each panel. Some manufacturers set the minimum order at just 10 square meters for custom panels, while others require 100 or even 300 square meters for specialty products. The following table gives you a better idea of how order volume affects unit price:

| Product Description | Unit Price Range | Minimum Order Quantity |

|---|---|---|

| Custom 3mm Thick Core Bee Honeycomb Aluminum Honeycomb Panel | $1.35-7.80 | 10 square meters |

| Aluminum Honeycomb Panels Price 10mm Aluminum Honeycomb Core Panel | $5.80-7 | 100 square meters |

| Quick-Install Sound Insulation Panels | $11.70-13.50 | 300 square meters |

You benefit from volume discounts when you reach certain thresholds. Most suppliers offer:

10-20% off when you order at least 500 square meters

25-40% off for orders of 2,000 square meters or more

Extra 5-8% savings if you sign an annual contract

Tip: If you plan to use aluminum honeycomb panels for multiple projects, consider negotiating an annual contract. You can lock in lower prices and ensure a steady supply.

Bulk pricing helps you manage your budget and get the best value for your investment. You should always ask suppliers about their discount policies and minimum order requirements before placing an order.

You see that aluminum honeycomb panels use a special sandwich structure. Two thin face sheets cover a lightweight honeycomb core. This design gives you strength and keeps the panel light. The honeycomb core often uses aluminum for the best strength-to-weight ratio. Some panels use other materials like polycarbonate foam or paper for the core. You can also choose face sheets made from stainless steel, high-pressure laminates, or aluminum with different finishes.

| Component | Description |

|---|---|

| Face Sheets | Two thin sheets that form the outer layers of the panel. |

| Core Material | Usually aluminum honeycomb for strength and low weight. |

| Core Structure | Honeycomb core provides low density and high stiffness. |

This structure helps you get panels that are strong, flat, and easy to handle.

You benefit from panels that weigh much less than solid metal sheets. The honeycomb core reduces density, so you can move and install panels with less effort. Lower weight means you save on transport costs and labor.

The sandwich design gives you high rigidity. Panels stay flat and strong, even under heavy loads. You can use them in places where stability matters, like walls or ceilings.

Aluminum honeycomb panels help limit heat transfer. The core design blocks airflow, so you get better insulation than with solid metal. This feature helps you keep buildings energy efficient.

Aluminum is non-combustible. You get panels that resist fire and moisture. This makes them safe for many uses, including public buildings and vehicles.

Tip: If you need panels for areas with strict safety rules, choose ones with an aluminum honeycomb core for the best fire resistance.

You find aluminum honeycomb panels in many industries. In architecture, you use them for ceilings in subway stations, curtain walls, and soundproof panels. In transportation, they work well for train floors, car doors, and aircraft wings. Cleanrooms use these panels for walls, ceilings, and equipment enclosures. You can also use them for portable homes, conference rooms, and raised flooring systems.

Common uses include:

Ceilings and walls in large buildings

Doors and partitions in cleanrooms

Floors and bulkheads in trains and buses

Rocket fairings and aircraft parts

You get panels that fit many needs, from strong building cladding to lightweight vehicle interiors.

You may wonder how aluminum honeycomb panels compare to composite panels with plastic cores. Both types offer good strength and flatness, but their performance differs in important ways. Composite panels often use a plastic honeycomb or foam core. This makes them lighter than panels with an aluminum core. You might choose composite panels for projects where weight is the main concern.

However, you should consider fire resistance and durability. Aluminum honeycomb panels provide better fire resistance because aluminum does not burn. Composite panels with plastic cores may not meet strict fire safety standards. Durability also matters. Aluminum honeycomb panels last longer and resist damage from impacts or harsh weather.

Here is a table that shows the main differences:

| Attribute | Aluminum Honeycomb Panels | Aluminum Composite Panels |

|---|---|---|

| Weight | Heavier due to aluminum core | Lighter due to plastic core |

| Fire Resistance | Good fire resistance | Varies based on core material |

| Durability | Very high durability | High durability |

Note: If you need panels for public buildings or transportation, you should choose aluminum honeycomb panels for better safety and long-term value.

You may also compare aluminum honeycomb panels to solid aluminum panels. Solid panels use more aluminum, which increases their weight. You get excellent structural strength with solid panels, but you may face higher transportation and installation costs. Aluminum honeycomb panels weigh less and offer better insulation. This helps you save money and energy in large projects.

The cost difference is important. Solid aluminum panels usually cost less per square meter, but you may pay more for handling and installation. Aluminum honeycomb panels provide a balance between strength, weight, and insulation.

| Panel Type | Cost Range (per m²) |

|---|---|

| Aluminum Honeycomb Panels | $50 – $120 |

| Solid Aluminum Panels | $40 – $80 |

Tip: If you want panels that are easy to install and help with energy savings, aluminum honeycomb panels are a smart choice.

When you compare all three options, you see clear differences in price, weight, fire resistance, and durability. Aluminum honeycomb panels cost more than composite panels, but you get better fire safety and longer life. Solid aluminum panels offer strong support, but they are heavy and less efficient for insulation.

You should think about your project needs. If you need lightweight panels for easy installation, composite panels may work. If you need strong panels for heavy loads, solid aluminum panels are a good option. For most architectural and transportation projects, aluminum honeycomb panels give you the best mix of safety, durability, and energy efficiency.

Choosing the right panel helps you save money and improve safety. Always match your choice to your project’s requirements.

When you choose aluminum honeycomb panels, the quality of the materials plays a big role in the final price. Higher-grade aluminum, like 5052 alloy, costs more because it offers better strength and corrosion resistance. You often see this alloy in demanding environments such as aviation and rail transit. The honeycomb core usually uses 3003 or 5052 aluminum alloys. These materials provide:

High density and superior strength

Lightweight properties that make handling and installation easier

Excellent corrosion resistance for extreme environments

Structural integrity from the honeycomb design

Advanced materials and precise manufacturing processes increase the cost, but you get panels that last longer and perform better.

You might need panels in special sizes, shapes, or with unique finishes. Customization lets you match your project’s exact needs, but it can also raise the price. When you request custom sizes or shapes, the manufacturer may need to adjust their production line. Special finishes, such as custom colors or textures, require extra materials and steps. Each change in configuration can add to the overall cost. If your project needs a unique look or fit, plan for a higher budget to cover these custom features.

Tip: Standard sizes and finishes usually cost less. If you want to save money, choose from the manufacturer’s regular options.

Shipping and import costs can make up a large part of your total expenses, especially if you order from overseas. The price depends on the destination, quantity, and weight of your order. For example, shipping eight panels weighing 124 kilograms from China to Malaysia costs about $999.71.

| Country | Quantity | Weight | Cost |

|---|---|---|---|

| Malaysia | 8 PC | 124 KGS | $999.71 |

You should also consider customs duties, taxes, and local delivery fees. These extra charges can affect your final budget. Always ask your supplier for a full breakdown of shipping and import costs before you place your order.

Note: Ordering in bulk can sometimes lower the shipping cost per panel, but larger shipments may face higher import taxes.

When you search for a manufacturer, you want to make sure you choose the right one. Start by checking the company’s certifications. Look for ISO 9001, which shows the company follows strict quality management standards. You should also check if the manufacturer has fire safety and environmental certifications. These prove the panels meet important safety and eco-friendly requirements.

Experience matters. A manufacturer with many years in the industry often delivers better products. You can ask how long the company has been making aluminum honeycomb panels. Companies with a long track record usually have better technology and more reliable quality.

Customer reviews give you real feedback. Read reviews on trusted websites or ask the supplier for references. Positive reviews show that other buyers trust the company. If you see many complaints, you may want to look elsewhere.

Tip: Always ask for sample panels before you place a large order. Samples help you check the quality for yourself.

You can find reliable manufacturers on several online platforms. Alibaba is one of the most popular sites for sourcing building materials from China. You can search for suppliers, compare prices, and read customer reviews. Made-in-China.com is another good platform. It lists many verified manufacturers and lets you request quotes directly.

Global Sources connects you with suppliers who export worldwide. This platform often features companies with export experience and international certifications. You can also use industry-specific trade shows or exhibitions. These events let you meet suppliers face-to-face and see their products up close.

Alibaba: Wide selection, user reviews, trade assurance

Made-in-China.com: Verified suppliers, direct quotes

Global Sources: Export-focused, international standards

Note: Always use the platform’s messaging system to keep records of your communication.

Before you choose a supplier, you need to verify their credentials. Ask for business licenses and certificates. Check if the company’s address and contact details match what you see online. You can use third-party inspection services to visit the factory and check production lines.

Request product test reports. These reports show if the panels meet safety and quality standards. You should also ask for a list of past projects. This helps you see if the supplier has experience with projects like yours.

If possible, schedule a video call or factory tour. This gives you a better idea of the company’s operations and professionalism.

Remember: Careful verification protects you from scams and low-quality products.

When you contact a manufacturer for aluminum honeycomb panels, you want clear answers. Asking the right questions helps you avoid surprises and ensures you get the best value. Here are important questions you should ask before placing an order:

You should ask for details about panel thickness, core material, face sheet thickness, and available sizes. Request a technical datasheet. This document shows you the panel’s structure and performance.

Ask about available coatings, such as PVDF, anodized, or powder coatings. Find out which finish works best for your application. Some finishes last longer outdoors, while others suit indoor use.

You need to know the smallest order you can place. Some manufacturers set a high MOQ for custom panels. Others allow small trial orders. This information helps you plan your purchase.

Request samples before you commit to a large order. Samples let you check the panel’s quality, finish, and color. Many suppliers offer free or paid samples.

Ask for certifications like ISO 9001, fire safety ratings, and environmental standards. Certified panels meet strict quality and safety requirements.

Find out how long it takes to produce and ship your order. Lead times vary based on order size and customization. You need this information to schedule your project.

Ask about the warranty period and what it covers. A good warranty protects you from defects and ensures long-term performance.

Ask about packaging methods to prevent damage during transport. Find out if the supplier handles shipping or if you need to arrange it. Request a shipping cost estimate.

Discuss payment options, such as deposits, balance payments, and accepted currencies. Clear payment terms help you avoid misunderstandings.

Request examples of past projects. References show you the supplier’s experience and reliability.

Tip: Write down these questions before you contact suppliers. Use their answers to compare offers and choose the best manufacturer for your needs.

| Question Topic | Why It Matters |

|---|---|

| Specifications | Ensures you get the right product |

| Surface Finish | Matches your application |

| MOQ | Fits your budget and project size |

| Samples | Lets you check quality |

| Certifications | Confirms safety and standards |

| Lead Time | Helps you plan your schedule |

| Warranty | Protects your investment |

| Packaging/Shipping | Prevents damage, clarifies costs |

| Payment Terms | Avoids confusion |

| References | Proves supplier reliability |

You get better results when you ask detailed questions. Careful communication helps you avoid mistakes and ensures a smooth buying process.

You want to compare suppliers before you make a decision. The table below shows sample prices and features from some of the top Chinese manufacturers. This helps you see the differences at a glance.

| Supplier Name | Price per m² (USD) | MOQ (m²) | Thickness Options (mm) | Surface Finishes Available | Certifications | Notable Features |

|---|---|---|---|---|---|---|

| Zhejiang Kangzhan New Materials Co. Ltd. | $25 – $35 | 200 | 6, 10, 14, 20, 25 | PVDF, FEVE, Anodized, PE | ISO 9001, Fire Safety | High rigidity, eco-friendly, custom sizes |

| Foshan Alstrong Building Materials | $28 – $40 | 300 | 6, 10, 15, 20 | PVDF, Powder, Anodized | ISO 9001 | Fast delivery, wide color range |

| Shanghai Alumtimes Industry Co. | $22 – $38 | 100 | 6, 10, 15, 20, 25 | PVDF, PE, Anodized | ISO 9001, SGS | Low MOQ, flexible customization |

| Henan Mingtai Aluminum Industrial | $30 – $45 | 500 | 10, 15, 20, 25 | PVDF, Powder | ISO 9001, CE | Large-scale production, export focus |

Note: Prices may change based on order size, thickness, and finish. Always ask for a detailed quote.

You should look at the strengths and weaknesses of each supplier. This helps you choose the best fit for your project.

Zhejiang Kangzhan New Materials Co. Ltd.

✅ Offers a wide range of thicknesses and finishes.

✅ Holds important certifications for quality and fire safety.

✅ Provides custom sizes and eco-friendly materials.

❗ Minimum order quantity is higher than some competitors.

Tip: If you want the best value for aluminum honeycomb panels, balance price, quality, and supplier reliability. Always request samples and check certifications before you buy.

You see aluminum honeycomb panels priced from $25 to $35 per square meter. Thickness, finish, and order volume affect your cost. You get panels that are lightweight, rigid, and fire-resistant. These features make them ideal for architecture and transportation.

Check certifications and reviews before you choose a manufacturer.

Compare quotes and product details for the best value.

Tip: Use this guide to request samples and compare suppliers. You make smarter decisions when you understand your options.

You usually find panels in the 4x8 feet size (about 1220 x 2440 mm). Many manufacturers also offer custom sizes to fit your project needs.

You should match panel thickness to your application. Thicker panels provide more strength and rigidity. For wall cladding, 10–20 mm works well. For ceilings or partitions, 6–10 mm is often enough.

You get strong fire resistance with aluminum honeycomb panels. The non-combustible aluminum core helps meet safety standards in buildings and vehicles.

You can choose from PVDF, FEVE, anodized, powder, and polyester PE coatings. Each finish offers different benefits for durability, color, and weather resistance.

You install panels using mechanical fasteners, adhesives, or mounting frames. Most panels arrive ready for quick installation, saving you time and labor.

You can use these panels outdoors. Select weather-resistant finishes like PVDF or powder coating for the best performance against rain, sun, and pollution.

You often see minimum orders starting at 10–200 square meters. Some suppliers allow small trial orders, especially for custom panels.