Views: 0 Author: Site Editor Publish Time: 2025-09-10 Origin: Site

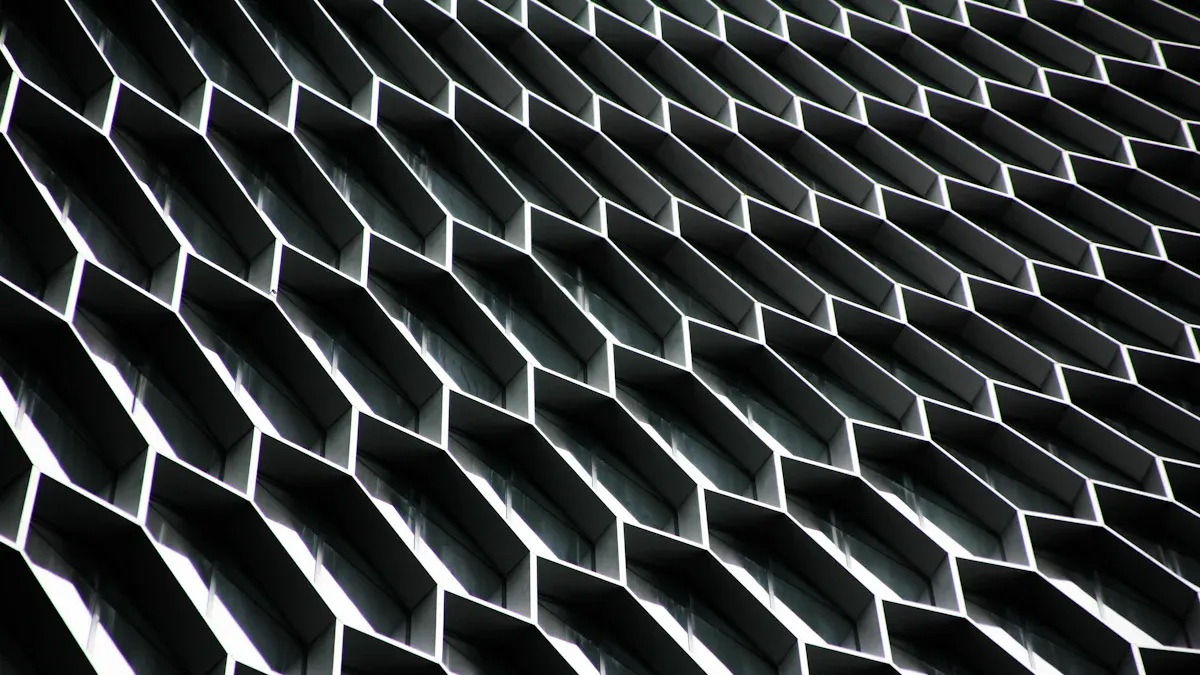

You can make aluminum honeycomb panels by following a precise sequence of manufacturing steps. Start with aluminum foil, then print adhesive lines, cut and stack the sheets, cure them in a heated press, and expand the block to create the honeycomb core. Next, trim and stabilize the core before bonding it between aluminum skins. Each step requires careful attention to detail for a strong, lightweight panel.

Prepare aluminum foil.

Apply adhesive lines.

Stack and cure sheets.

Expand to form honeycomb.

Trim and stabilize the core.

Bond core between skins.

Start with high-quality aluminum foil. Choose the right alloy and thickness for strength and weight balance.

Apply adhesive carefully. Clean and prepare surfaces to ensure strong bonding between layers.

Use proper tools for cutting and expanding. Sharp tools create clean edges and uniform honeycomb structures.

Inspect materials before assembly. Check for defects in aluminum skins and ensure coatings are intact.

Follow safety protocols. Wear gloves, safety glasses, and protective clothing to prevent injuries during production.

Maintain a clean workspace. A tidy area reduces the risk of accidents and ensures better quality panels.

Regularly inspect and maintain finished panels. Clean them with mild detergent and check for damage to extend their lifespan.

Choose the right adhesives. Use high-strength options designed for aluminum to ensure durability and performance.

You need high-quality aluminum foil to create the honeycomb core. The choice of alloy and thickness affects the strength, weight, and performance of your panels. Most manufacturers use alloys like 3003, 3004, and 5052 because they offer a good balance of flexibility and durability. The thickness of the foil usually ranges from 0.02 mm to 0.08 mm. Thinner foil makes the panel lighter, while thicker foil increases strength.

Here is a quick reference table for common alloys and thicknesses:

| Alloy Type | Thickness Range (mm) |

|---|---|

| 3004 | 0.02 - 0.06 |

| 3003 | 0.02 - 0.08 |

| 5052 | 0.03 - 0.08 |

You can source these materials from specialized suppliers. Zhejiang Kangzhan New Materials Co. Ltd. is one example of a company that provides high-quality aluminum foil for aluminum honeycomb panels.

Tip: Always check the surface quality of the foil. Clean, flat foil helps you achieve better bonding and a more uniform honeycomb structure.

Adhesives play a key role in bonding the aluminum foil layers and attaching the honeycomb core to the skins. You should select adhesives that provide strong bonds and can handle the stresses of expansion and pressing.

Solfre 2 Honeycomb: This two-part polyurethane adhesive is popular for its high bond strength, even on minimal contact surfaces.

Two-part polyurethane adhesives maintain flexibility while ensuring a secure hold.

These adhesives work well with both the core and the skins, helping you achieve panels with excellent durability.

Note: Always mix adhesives according to the manufacturer’s instructions. Proper mixing ensures maximum bond strength and prevents weak spots in your panels.

You need core expansion tools to transform stacked and bonded aluminum foil sheets into the honeycomb structure. These tools pull the sheets apart, creating the hexagonal cells that give aluminum honeycomb panels their unique properties. Manual expansion tools work for small projects, but you should use mechanical or pneumatic expanders for larger production runs. These tools help you achieve consistent cell size and shape, which is important for panel strength and flatness.

Using the right expansion tool helps you avoid uneven cells and ensures your panels meet quality standards.

You need aluminum skins to complete your honeycomb panels. These skins provide strength, rigidity, and a smooth surface. Most manufacturers use high-quality aluminum alloys such as 1100, 3003, 5005, or 6063. The thickness of the skins usually ranges from 0.5 mm to 1.5 mm. Thicker skins increase durability and impact resistance. Thinner skins help reduce weight.

You should select skins based on your application. For architectural facades, thicker skins offer better flatness and strength. For elevator interiors or transit vehicles, lighter skins help reduce overall weight.

Coatings protect the aluminum skins from corrosion, UV rays, and wear. You can choose from several types of coatings:

Fluorocarbon (PVDF) Coating: This coating provides excellent weather resistance and color stability. It works well for outdoor panels.

Polyester Coating: This option suits indoor applications. It offers good durability and a wide range of colors.

Anodized Finish: This finish increases corrosion resistance and gives the panel a metallic look.

Tip: Always inspect the coated skins for scratches or uneven surfaces before assembly. High-quality coatings ensure your panels stay attractive and last longer.

You can source pre-coated aluminum skins from suppliers like Zhejiang Kangzhan New Materials Co. Ltd. They offer a variety of alloys and finishes to match your project needs.

You need precise cutting tools to shape the aluminum foil, skins, and finished panels. Accurate cuts help you achieve clean edges and proper fit during assembly.

Common cutting tools include:

Shears: Use manual or electric shears for cutting aluminum foil and thin skins.

Guillotine Cutters: These machines make straight cuts on large sheets. They work well for batch processing.

CNC Routers: Computer-controlled routers provide high precision for complex shapes and custom sizes.

Utility Knives: Use these for trimming small sections or making minor adjustments.

You should keep your cutting tools sharp and clean. Dull blades can cause jagged edges and damage the material. Always measure twice before cutting to avoid mistakes.

Note: Wear gloves when handling sharp tools and aluminum sheets. This helps prevent cuts and injuries.

You must use proper safety gear when making aluminum honeycomb panels. Safety gear protects you from sharp edges, adhesives, and machinery.

Essential safety equipment includes:

Gloves: Protect your hands from cuts and adhesive exposure.

Safety Glasses: Shield your eyes from flying debris during cutting and pressing.

Respirators: Use these when working with adhesives or coatings that release fumes.

Protective Clothing: Wear long sleeves and pants to prevent skin contact with chemicals and sharp materials.

Ear Protection: Use earplugs or earmuffs when operating loud machinery.

You should always follow safety instructions for each tool and material. Keep your workspace clean and organized to reduce accidents.

Safety Reminder: Never skip safety gear, even for small tasks. Proper protection ensures you can work efficiently and avoid injuries.

You start by cutting the aluminum foil to the correct size. Use sharp shears or a guillotine cutter for straight, clean edges. Measure each sheet carefully before you cut. This step helps you avoid waste and ensures that every piece fits together during assembly. If you plan to make several panels, stack the foil sheets and cut them together. This method saves time and keeps the sizes consistent. Always check the edges after cutting. Smooth out any rough spots with a fine file or sandpaper. Clean cuts help you achieve a uniform honeycomb structure later.

Tip: Wear gloves when handling cut foil. The edges can be very sharp and may cause injuries.

Clean aluminum foil gives you better bonding results. Dust, oil, or fingerprints can weaken the adhesive bond. Start by wiping each sheet with a lint-free cloth. Use a solvent like isopropyl alcohol to remove grease or residue. Let the foil dry completely before moving to the next step. For best results, work in a clean area. Avoid touching the foil with bare hands after cleaning. Even small amounts of dirt can affect the strength of your aluminum honeycomb panels.

Applying adhesive to the foil is a key step in making strong panels. Industry standards recommend several important practices for this process. First, prepare the surface by wiping it with a solvent and lightly abrading it. This creates a clean, dry, and slightly rough surface that helps the adhesive stick better. Some manufacturers use primers to improve adhesion, especially when working with challenging surfaces.

You can apply adhesive by hand for small projects. For larger batches, automated systems give you more consistent results. The table below shows common industry practices for adhesive application:

| Aspect | Details |

|---|---|

| Surface Preparation | Solvent wiping and abrasion ensure a clean, dry surface for adhesion. |

| Surface Roughening | Sanding or blasting creates micro-textures for better mechanical grip. |

| Use of Primers | Primers boost adhesion and durability, especially on tough substrates. |

| Application Methods | Manual for precision; automated for large-scale, consistent production. |

Apply the adhesive in even lines or patterns, following the product instructions. Make sure the coverage is uniform. Uneven adhesive can lead to weak spots or defects in the finished panel. After applying the adhesive, stack the sheets as soon as possible to prevent dust from settling on the sticky surface.

You start by stacking aluminum foil sheets to build the honeycomb core. Uniform stacking is essential for strength and stability. You should align each sheet carefully to avoid gaps or overlaps. Researchers have found that the way you stack layers affects the mechanical properties of the core. Here are some stacking techniques that help you achieve uniformity:

Align each sheet edge-to-edge for consistent cell formation.

Use tandem stacking to increase elastic modulus and collapse stress.

Add more layers to boost energy absorption efficiency.

Apply gentle pressure to keep sheets flat and prevent shifting.

Tip: Consistent stacking leads to better performance in your finished panels. Take your time during this step to avoid defects later.

After stacking, you need to bond the sheets together. This step creates the honeycomb structure and gives the core its strength. You can use adhesive films or epoxy pastes, depending on your project size and requirements. Adhesive films work well because they concentrate around the cell edges, increasing strength while using less adhesive. Epoxy adhesives are common in aerospace and marine applications.

Here is a table showing effective bonding methods and their benefits:

| Method | Description | Benefits |

|---|---|---|

| Adhesive Films | Adhesive concentrates around cell edges. | 3-5x strength increase, less adhesive needed, high peel strength |

| Epoxy Liquid/Paste and Film | Used in demanding industries for honeycomb panel construction. | Strong bonds, corrosion protection, durability |

You should always prepare the surface before bonding. Clean and roughen the foil to help the adhesive stick. Temperature and mechanical properties matter, especially for panels used in tough environments.

| Consideration | Importance |

|---|---|

| Surface Preparation | Essential for strong bonds |

| Mechanical Properties | Critical for durability and performance |

Note: Proper bonding ensures your aluminum honeycomb panels stay strong and reliable in real-world use.

Once the adhesive cures, you expand the stacked block to form the honeycomb pattern. You pull the sheets apart using expansion tools, which create the hexagonal cells. Manual expansion works for small projects, but mechanical expanders give you more control and consistency. You should expand the core slowly to avoid tearing or uneven cells.

Follow these steps for successful expansion:

Check that the adhesive is fully cured.

Place the stacked block in the expansion tool.

Pull the sheets apart gently to form uniform hexagonal cells.

Inspect the core for any defects or misaligned cells.

Tip: Uniform expansion leads to better flatness and compressive strength. Inspect the core after expanding to catch any issues early.

You need to prepare the aluminum skins before you assemble the panel. Proper preparation helps you achieve strong adhesion and long-lasting performance. Start by inspecting each skin for scratches, dents, or contamination. Clean the surface with a lint-free cloth and a suitable solvent, such as isopropyl alcohol. Avoid using petrol or paint thinners because these can leave residues that weaken the bond.

You should also check the compatibility of the adhesive with both the honeycomb core and the aluminum skins. Select an adhesive that offers high shear and peel strength. This prevents the skins from separating or peeling off during use. Match the adhesive to the temperature and humidity conditions in your workspace. If you plan to use the panels outdoors, choose adhesives that resist moisture and chemicals.

Here is a table showing best practices for preparing panel skins:

| Best Practice | Description |

|---|---|

| Substrate Compatibility | Ensure the adhesive matches the core and panel sheet materials for strong adhesion. |

| Shear Strength | Pick an adhesive that resists horizontal stress. |

| Peel Strength | Use an adhesive that prevents delamination or peeling. |

| Curing Conditions | Match adhesive selection with the temperature and humidity of your environment. |

| Environmental Resistance & Performance | Choose adhesives that withstand moisture, temperature changes, and chemicals for outdoor use. |

Tip: Always inspect the skins after cleaning. Even small particles can affect the bond and reduce panel strength.

You must bond the honeycomb core to the prepared skins with care. Begin by cleaning all surfaces with a good degreasing agent, such as IPA wipes. Avoid low-grade alcohols or paint thinners. Gently abrade the honeycomb surfaces with an emery cloth to remove the oxide layer. This step increases the surface area and improves adhesive grip. Wipe the surfaces again with a solvent to remove any loose particles.

Clean surfaces with IPA wipes.

Avoid petrol, paint thinners, or low-grade alcohols.

Gently abrade honeycomb surfaces with emery cloth.

Wipe surfaces again with solvent before applying adhesive.

Apply the adhesive evenly to both the core and the skins. Use a roller or brush for small panels. For larger panels, automated systems help you achieve consistent coverage. Place the honeycomb core between the skins, making sure everything lines up correctly. Press the assembly lightly to ensure good contact.

Note: You should avoid excessive adhesive, which can squeeze out and create uneven surfaces. Use just enough to cover the bonding area.

You need to press the assembled panel to cure the adhesive and create a strong bond. Place the panel in a heated press or autoclave. Set the pressure according to the adhesive manufacturer's recommendations. High pressure helps the adhesive flow and fill gaps, but too much pressure can crush the honeycomb core.

Monitor the temperature and humidity during pressing. These factors affect how the adhesive cures. Most adhesives require a specific temperature range for optimal strength. Keep the panel under pressure until the adhesive fully cures. This process usually takes several hours.

Tip: Use a flat press bed to maintain panel flatness. Uneven pressure can cause warping or defects.

You can now remove the panel from the press and inspect it for any defects. Check for delamination, uneven surfaces, or trapped air bubbles. Proper pressing ensures your aluminum honeycomb panels have excellent rigidity, flatness, and durability.

You need to trim your aluminum honeycomb panel after pressing. This step removes excess material and creates clean, straight edges. Use a sharp utility knife or a CNC router for best results. Measure each side before you cut. Mark the lines with a ruler and a pencil. Cut slowly to avoid damaging the skins or the honeycomb core. Smooth rough edges with a fine file or sandpaper. Clean edges help you achieve a professional look and make installation easier.

Tip: Always wear gloves and safety glasses when trimming panels. Sharp edges can cause injuries.

You must seal the edges of your panel to protect it from moisture and corrosion. Edge sealing also improves fire resistance and prevents bacteria or mildew from entering the core. PVC edge banding works well for aluminum honeycomb panels. It is lightweight and strong. You can apply it with adhesive or heat. Press the banding firmly along each edge. Make sure there are no gaps. Sealed edges extend the life of your panel and keep it looking new.

Here is a table showing the features of PVC edge banding:

| Feature | Description |

|---|---|

| Edge Sealing | Mainly PVC edge banding |

| Function | Waterproof; moisture-proof; fireproof; antibacterial; mildew-proof; corrosion-resistant; light weight; strong impact resistance; large bearing capacity |

Note: Sealing the edges is important for panels used in humid or outdoor environments.

You should apply a surface coating to your aluminum honeycomb panel for extra durability and a better appearance. Coatings protect the aluminum from corrosion, scratches, and UV rays. You can choose from several types of coatings. Spraying creates different visual effects. Aluminum plating and galvanizing increase durability and corrosion resistance. Oxidation and anodizing improve surface hardness. Protective coatings prevent damage from long-term air exposure. Polyester, epoxy, and acrylic coatings offer strong finishes and enhance color.

Here is a table showing common surface coatings and their purposes:

| Coating Type | Purpose |

|---|---|

| Spraying | Creates various visual effects |

| Aluminum Plating | Enhances durability and aesthetic appeal |

| Galvanizing | Provides corrosion resistance |

| Oxidation | Protects the aluminum from environmental factors |

| Anodizing | Improves surface hardness and corrosion resistance |

| Protective Coating | Prevents corrosion from long-term air exposure |

| Polyester | Offers a durable finish |

| Epoxy | Provides strong adhesion and chemical resistance |

| Acrylic | Enhances aesthetic appeal and UV resistance |

You can select a coating based on your project needs. For outdoor panels, choose anodizing or galvanizing for maximum protection. For indoor panels, polyester or acrylic coatings work well. Apply the coating evenly and let it cure fully before handling the panel.

Tip: Inspect the coated surface for bubbles or streaks. A smooth finish improves both performance and appearance.

You want strong bonding in your panels. Start by preparing every surface. Clean the aluminum skins and honeycomb core with a solvent. Lightly abrade each area to help the adhesive grip. Use the right adhesive for your application. Distribute the load evenly by using higher density core inserts or monolithic inserts. If you need extra strength, bond in an oversized insert and rabbet the core. This lets a potting agent lock in and spread the load. You can also add a backing plate for local reinforcement. Higher density honeycomb eases load transition and improves overall adhesion.

Tip: Always check that the adhesive covers all bonding areas. Gaps or thin spots can weaken the panel.

Prepare surfaces by cleaning and abrading.

Choose adhesives with high shear and peel strength.

Use inserts and backing plates for better load distribution.

Select higher density honeycomb for tough applications.

You may encounter defects during production. Knowing how to prevent them helps you make high-quality aluminum honeycomb panels. Here is a table showing common defects and how to avoid them:

| Defect | Description | Prevention Method |

|---|---|---|

| Reduced Penetration | Adhesive does not fill surface irregularities | Apply adhesive properly and prepare surfaces well |

| Early Unpressurization | Incomplete bonding and weak structure | Maintain correct pressurization time during curing |

| Oxidation or Oil Contamination | Oxide layer or oil blocks adhesion | Clean all surfaces thoroughly before bonding |

| Non-flat Surfaces | Uneven bonding, possible de-gluing | Align and flatten surfaces before assembly |

| Ineffective Perforation | Trapped air, weak bonds | Use correct perforation patterns and sizes |

Flatness is important for many uses. Architectural panels need very low flatness tolerance, often just a few millimeters over a large area. Industrial panels require stable surfaces for equipment. Aerospace panels demand extremely strict flatness for safety and performance.

| Application Type | Flatness Tolerance Description |

|---|---|

| Architectural | Very low tolerance, within a few millimeters over large areas |

| Industrial | Stable surfaces, less strict than architectural |

| Aerospace | Extremely strict, ensures aerodynamics and structural integrity |

Tip: Inspect every panel for defects before installation. Early detection saves time and money.

You must follow safety steps when making and installing panels. Wear gloves to protect your hands from sharp edges. Use safety glasses to shield your eyes during cutting and pressing. Always wear a respirator when working with adhesives or coatings that release fumes. Protective clothing keeps chemicals and sharp materials away from your skin. Ear protection helps when you use loud machines.

Aluminum honeycomb panels offer excellent fire resistance. Many panels meet A2 and B1 ratings under EN13501-1 standards. A2 panels are non-combustible, produce no smoke, and do not drip flammable material.

| Fire Rating | Characteristics |

|---|---|

| A2 | Non-combustible |

| s1 | No smoke |

| d0 | No flammable dropping |

Vibration damping is another safety feature. The honeycomb core absorbs impact energy through plastic deformation. This reduces noise and vibration in elevators, vehicles, and buildings.

Honeycomb sandwich panels, with a core bonded between two thin facesheets, are widely used in aerospace, automotive, and marine applications. You benefit from their excellent density-specific properties and vibration damping, especially when you fill honeycomb cells with foam or particulate fillers.

Tip: Always follow safety instructions for tools and materials. A clean, organized workspace helps prevent accidents.

You need to handle aluminum honeycomb panels with care to prevent damage during installation. Always use proper lifting equipment and techniques. Lift panels by their edges or designated lifting points. This helps you avoid bending or scratching the surface. Wearing gloves keeps fingerprints and marks off the panels.

Keep panels protected in high-traffic areas. Leave protective coatings on the panels or cover them with plywood or ISO board while construction continues. Always follow the manufacturer’s handling instructions. At least two people should move each panel to reduce the risk of accidents.

Here is a table that summarizes key handling procedures:

| Procedure | Description |

|---|---|

| Protect pallets | Store pallets away from rain, moisture, and condensation. |

| Stacking | Stack only identical-size pallets, up to 6 high, not exceeding 2 meters. |

| Storage duration | Avoid storing panels for more than 6 months. |

| Stacking panels | Do not place items between stacked panels to prevent marks. |

Use appropriate lifting equipment.

Lift by edges or lifting points.

Wear gloves to avoid surface marks.

Tip: Keep panels covered until you are ready to install them. This protects the finish and prevents accidental damage.

You must secure aluminum honeycomb panels using effective mounting techniques. Use at least one fastener per side of each panel, except at corners. For every square meter, install a minimum of eight fasteners. Stagger fasteners for adjacent panels with a spacing of 50 mm. This helps distribute the load and keeps panels stable.

Anchors play a key role in mounting. Place at least one anchor per side, spaced 300–500 mm apart. For reinforced concrete, ensure the anchorage depth exceeds 30 mm. For light wall bases, use more than 50 mm. Most installers use a depth of 60 mm for anchors to guarantee stability.

Use at least one fastener per side.

Install a minimum of eight fasteners per square meter.

Stagger fasteners with 50 mm spacing.

Anchor panels with a depth of 60 mm for best results.

Note: Always check the mounting surface for flatness before installation. Proper mounting ensures the panels remain secure and maintain their flat appearance.

You can extend the lifespan of aluminum honeycomb panels with regular maintenance. Clean the panels routinely using a soft cloth and mild detergent. Avoid harsh chemicals that can damage the finish. Identify stains early and use gentle solutions to remove them without abrasive scrubbing.

Set up a regular inspection schedule. Look for damage, cracks in sealants, or worn gaskets. Address any issues promptly to maintain insulation and weather resistance. For minor scratches or dents, use touch-up paint. Always check sealants and coatings for cracks and repair them as needed.

Clean panels regularly with mild detergent.

Remove stains gently without abrasive scrubbing.

Inspect panels and sealants for damage.

Check gaskets for wear.

Repair minor scratches with touch-up paint.

Avoid harsh chemicals.

Clean and inspect after severe weather.

Tip: Routine care keeps panels looking new and performing well for years. Regular inspections help you catch problems early and avoid costly repairs.

You can make aluminum honeycomb panels by following these essential steps:

Cut and prepare aluminum sheets.

Spray and form the honeycomb core.

Add the core and composite the layers.

Finish with trimming and coating.

Material selection matters. Choose panels with high fire ratings, strong insulation, and reliable impact resistance. Store panels flat and dry. Use safety harnesses for high-rise installations. The table below highlights practical advice for best results:

| Step | Description |

|---|---|

| 1 | Print adhesive lines on aluminum sheets. |

| 2 | Cut and stack foil to size. |

| 3 | Use a heated press to bond sheets. |

| 4 | Expand and add face sheets. |

Careful attention to each step ensures durable, safe, and high-quality panels.

The honeycomb core spreads force across the panel. You get high strength with low weight. The hexagonal cells resist compression and bending. This structure gives you excellent rigidity and flatness.

Yes, you can cut panels using a sharp utility knife or a CNC router. Always wear gloves and safety glasses. Measure carefully before cutting. Smooth the edges after you finish.

Yes, these panels offer excellent fire resistance. The aluminum core does not burn. Many panels meet A2 and B1 fire ratings. You can use them in places where fire safety matters.

Use a soft cloth and mild detergent for cleaning. Avoid harsh chemicals. Inspect panels regularly for damage or worn sealants. Touch up scratches with paint. Routine care keeps your panels looking new.

You can use these panels in building facades, elevator interiors, cleanrooms, and transit vehicles. They work well where you need lightweight, strong, and flat materials.

Yes, you should use high-strength adhesives designed for aluminum bonding. Always follow the manufacturer’s instructions. Proper adhesive choice ensures strong, durable panels.

Prepare all surfaces by cleaning and abrading. Use the right amount of adhesive. Press panels evenly. Inspect for flatness and trapped air. Early checks help you avoid costly mistakes.

You can source panels and materials from suppliers like Zhejiang Kangzhan New Materials Co. Ltd. They offer high-quality aluminum foils, skins, and finished panels for many applications.