Views: 0 Author: Site Editor Publish Time: 2025-09-10 Origin: Site

Aluminum honeycomb panels deliver outstanding performance in construction, transportation, cleanrooms, and industrial settings. You benefit from a structure that features two thin aluminum skins bonded to a lightweight honeycomb core, providing high rigidity, superior fire resistance, and full recyclability. Leading brands like Zhejiang Kangzhan New Materials Co. Ltd. supply these panels for projects prioritizing sustainability and durability.

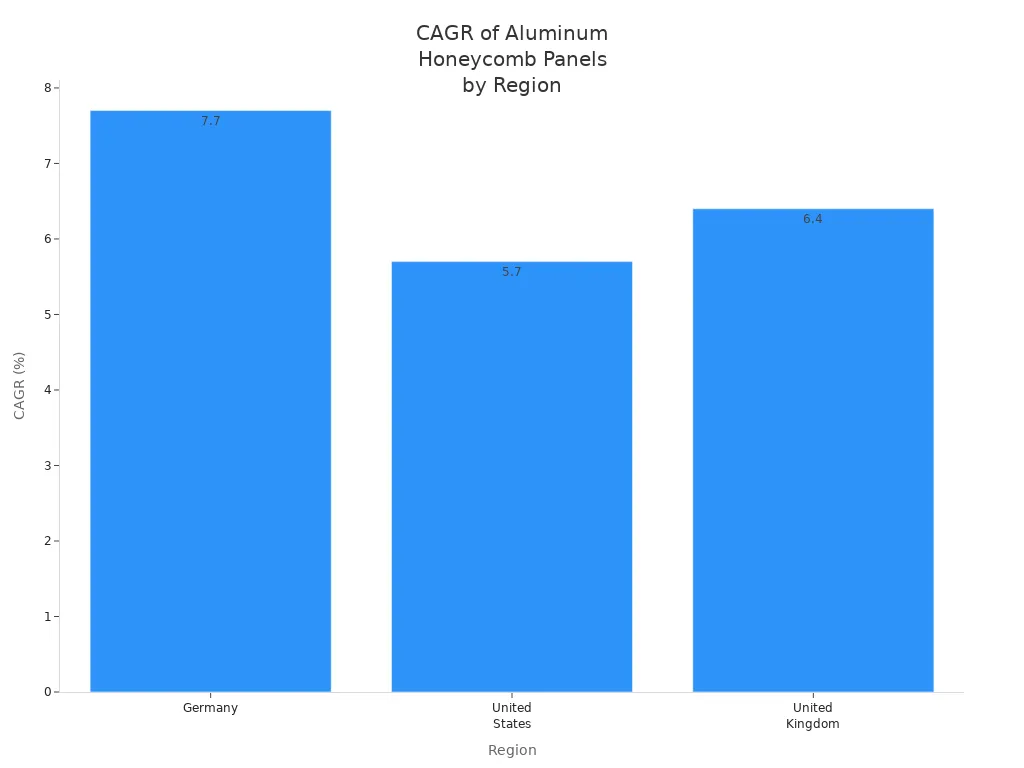

| Region | CAGR (%) | Common Applications |

|---|---|---|

| Germany | 7.7 | High-end architecture, transportation, luxury commercial interiors, fire safety, thermal control |

| United States | 5.7 | Defense, aerospace, construction, aircraft interiors, military shelters, energy-efficient buildings |

| United Kingdom | 6.4 | Building renovation, energy-efficient cladding, marine interiors, aviation components |

Aluminum honeycomb panels are lightweight yet strong, making them ideal for construction and transportation applications.

These panels offer excellent fire resistance, ensuring safety in high-risk environments like schools and hospitals.

The unique honeycomb structure provides superior thermal insulation, helping to reduce energy costs in buildings.

Aluminum honeycomb panels are fully recyclable, supporting sustainability and reducing environmental impact.

Customization options for size, thickness, and surface finishes allow for tailored solutions to meet specific project needs.

The panels' rigidity and flatness enhance structural integrity, making them suitable for demanding industrial applications.

Using aluminum honeycomb panels can lead to long-term cost savings due to their durability and low maintenance requirements.

These panels are versatile, finding applications in architecture, cleanrooms, automotive, and aerospace industries.

You can transform building facades with aluminum honeycomb panels. These panels offer a lightweight solution that makes installation easier and reduces the load on your structure. Their high strength-to-weight ratio ensures your facade remains flat and stable, even on large surfaces. You also gain enhanced thermal and sound insulation, which helps maintain comfortable indoor environments. The fire-resistant properties of aluminum honeycomb panels improve safety for your building. You have the freedom to customize shapes, colors, and finishes, allowing for creative architectural designs. Their durability and recyclability make them a sustainable choice for modern construction.

Lightweight material simplifies handling and installation.

High strength-to-weight ratio supports structural integrity.

Enhanced thermal and sound insulation improves energy efficiency.

Fire resistance increases building safety.

Design flexibility enables innovative facades.

Sustainable and recyclable for eco-friendly projects.

Long-term cost savings due to durability.

You can use aluminum honeycomb panels for ceilings in offices, shopping malls, and public spaces. Their flat surface creates a clean, professional look. These panels absorb sound, helping you reduce noise levels and create a more comfortable environment. Their lightweight nature makes installation quick and easy, while their rigidity ensures the ceiling remains stable over time. You can select different finishes to match your interior design.

Aluminum honeycomb panels work well for sun shades and slats. You can customize their shape and size to control sunlight and heat gain in your building. Their lightweight construction allows for easy installation, and their strength ensures long-lasting performance. Sun shades made from these panels help you improve energy efficiency by reducing the need for artificial cooling.

You can enhance elevator interiors with aluminum honeycomb panels. Their lightweight design reduces the overall weight of the elevator car, which can improve energy efficiency. The panels provide high strength and durability, ensuring your elevator withstands daily use. Their flat surface allows you to apply decorative finishes easily, creating a stylish and comfortable space for passengers.

Aluminum honeycomb panels play a key role in transit vehicles such as cars, buses, commercial vehicles, and motorsports. You benefit from reduced vehicle mass, which leads to better fuel efficiency and lower operating costs. The panels offer high strength and durability, making them suitable for demanding transportation environments. Their vibration-damping properties improve passenger comfort and protect vehicle components.

| Type of Transit Vehicle | Documented Benefits |

|---|---|

| Cars | Lightweight, improved fuel efficiency |

| Buses | High strength, durability |

| Commercial Vehicles | Enhanced performance, safety |

| Motorsports | Retains strength and rigidity |

You can use aluminum honeycomb panels in automotive applications to reduce vehicle weight and improve fuel economy. Their strength and rigidity help maintain safety standards while allowing for innovative design features. You also gain long-term durability, which lowers maintenance costs.

Aluminum honeycomb panels help you maintain strict cleanliness standards in cleanroom environments. Their smooth surfaces make cleaning easy, which is essential for controlling contamination. These panels resist chemicals and minimize dust and microbial growth, supporting hygiene in laboratories, pharmaceutical facilities, and electronics manufacturing. Their durability reduces maintenance needs, saving you time and resources.

Minimize dust and microbial growth for better cleanliness.

Smooth surfaces allow for easy cleaning.

Chemical resistance supports contamination control.

Durable construction reduces maintenance requirements.

| Sector | Market Share |

|---|---|

| Transportation | N/A |

| Construction | N/A |

| Others | N/A |

Aluminum honeycomb panels play a vital role in modern industry. You see these panels used in tool machines and machine surfaces because they offer a unique combination of strength, flatness, and lightweight construction. When you choose panels from Zhejiang Kangzhan New Materials Co. Ltd., you gain reliable performance for demanding environments.

You improve tool machine design by using aluminum honeycomb panels. These panels provide high rigidity, which helps your machines maintain accuracy during operation. You benefit from reduced weight, making it easier to move and install equipment. The panels also resist vibration, which protects sensitive components and extends the life of your machines. You notice that maintenance becomes simpler because the panels do not warp or deform under stress.

Tip: When you select aluminum honeycomb panels for tool machines, you increase energy efficiency and reduce downtime.

You rely on flat and stable surfaces for automatic machines. Aluminum honeycomb panels deliver exceptional flatness, which ensures precise movement and operation. You find these panels easy to clean, which supports hygiene in medical and food processing equipment. Their durability means you spend less time on repairs and replacements. You also see improved safety and stability, especially in environments where heavy loads and frequent use are common.

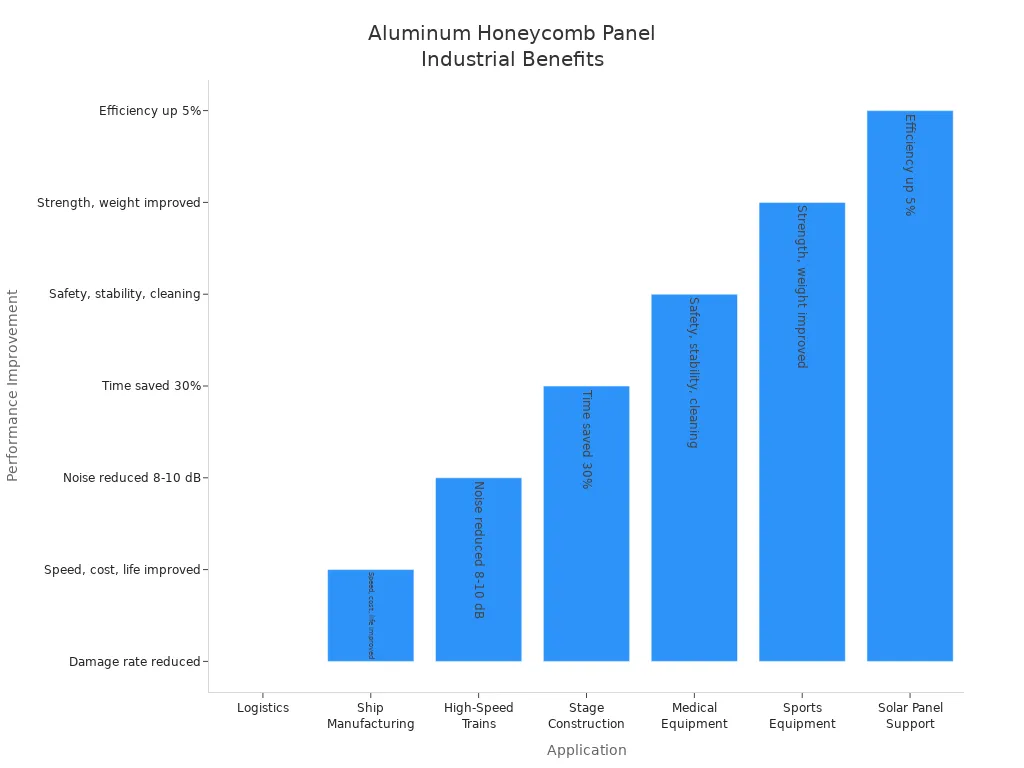

Here is a table showing how different industrial applications benefit from aluminum honeycomb panels:

| Application | Performance Improvement |

|---|---|

| Logistics | Damage rate during transportation reduced from 5% to less than 1% for fragile electronic products. |

| Ship Manufacturing | Increased sailing speed, reduced maintenance costs, and extended service life of decoration materials. |

| High-Speed Trains | Noise reduction of 8-10 decibels at 300 km/h, enhancing passenger comfort. |

| Stage Construction | Construction time saved by nearly 30% compared to traditional materials. |

| Medical Equipment | Ensures safety and stability during use, facilitating cleaning and disinfection. |

| Sports Equipment | Enhanced strength and reduced weight, improving performance for professional athletes. |

| Solar Panel Support | Increased power generation efficiency by about 5% without adding significant weight to roofs. |

You can see how aluminum honeycomb panels help you achieve better results in many industrial fields. For example, you reduce damage rates in logistics, save time in stage construction, and improve comfort in high-speed trains.

When you use aluminum honeycomb panels, you gain advantages that support innovation and efficiency in your industry. You make your machines safer, more reliable, and easier to maintain.

You notice the difference as soon as you handle aluminum honeycomb panels. The panels feel much lighter than solid aluminum sheets or other alternatives. This lightweight property makes transportation and installation easier for you. You can lift and position panels with less effort, which helps speed up construction and reduces labor costs. The honeycomb core inside each panel uses less material while maintaining strength. You see the benefits in many applications, from building facades to vehicle interiors.

Aluminum honeycomb panels can be up to 80% lighter than solid aluminum sheets.

You reduce the load on supporting structures, which can lower overall project costs.

Lighter panels help improve energy efficiency in transportation by reducing vehicle weight.

You gain flexibility in design because lightweight panels allow for larger spans and creative shapes. You also improve safety, since lighter materials are easier to handle and less likely to cause injury during installation.

You rely on rigidity when you need panels that stay flat and strong under stress. Aluminum honeycomb panels deliver impressive rigidity thanks to their sandwich structure. The honeycomb core supports the outer skins, preventing bending and warping. You see this advantage in architectural facades, ceilings, and machine surfaces. The panels maintain their shape even when exposed to heavy loads or frequent use.

Here is a comparison of rigidity and related properties:

| Property | Aluminum Honeycomb Panels | Other Panel Types |

|---|---|---|

| Rigidity | High | Varies |

| Strength-to-Weight Ratio | Impressive | Generally Lower |

| Application Suitability | High-Specification | Varies |

You choose aluminum honeycomb panels for projects that demand high performance. The panels support large, flat surfaces without sagging. You also benefit from their strength-to-weight ratio, which means you get strong panels without extra weight. This feature makes them ideal for elevators, cleanrooms, and industrial machines.

You need panels that can withstand pressure and heavy loads. Aluminum honeycomb panels offer superior compressive strength, which means they resist crushing and deformation. The hexagonal core structure distributes force evenly, protecting the panel from damage. You see this benefit in load-bearing walls, floors, and machine surfaces.

The maximum bearing capacity of the Type 3 aluminum honeycomb panel increased from 28 to 34.7 kN.

The compressive performance of the Type 3 panel was superior to that of the Type 1 panel.

The eccentric lateral compression performance of the wall end column honeycomb board improved significantly, with an ultimate bearing capacity increase of 23% when the eccentric distance was 7 mm.

You rely on this strength for demanding environments. The panels hold up under repeated use and heavy equipment. You also notice improved safety, since strong panels reduce the risk of structural failure. This feature makes aluminum honeycomb panels a smart choice for industrial and architectural projects where reliability matters most.

You notice the difference when you work with aluminum honeycomb panels. These panels deliver outstanding flatness, which matters in both architectural and industrial settings. A flat panel gives your building facade a sleek, professional look. You avoid unsightly bumps or waves that can lower the quality of your project. In industrial applications, flatness helps you achieve stable surfaces. For example, you get better results in T-shirt screen printing because the panel does not warp or bend.

Aesthetic Appeal: You create a modern, high-quality appearance for facades and interiors.

Functionality: You rely on flat panels for precise work, such as printing or assembly.

Ease of Installation: You fit panels together quickly and accurately, saving time on large projects.

Structural Integrity: You ensure even load distribution, which boosts safety and performance in demanding environments.

Flatness also makes cleaning and maintenance easier. You spend less time fixing problems caused by uneven surfaces. When you choose panels from Zhejiang Kangzhan New Materials Co. Ltd., you get consistent flatness across every piece.

You benefit from excellent insulation when you use aluminum honeycomb panels. The hexagonal core design traps air and slows down heat transfer. This structure gives you superior thermal insulation compared to solid aluminum sheets. You keep indoor spaces comfortable and reduce energy costs. You also protect sensitive equipment from temperature changes in industrial settings. The panels absorb energy from impacts, which adds another layer of protection.

Aluminum honeycomb panels perform well in high-performance environments. You see them used in aerospace, building cladding, and cleanrooms. Their lightweight nature does not compromise their ability to manage heat.

You test the thermal response of panels under rising temperatures.

You find that smaller panels maintain their shape and strength, even in tough conditions.

You observe that the average temperature rise stays stable, showing how well these panels insulate.

You choose aluminum honeycomb panels when you need both strength and effective thermal management.

You solve vibration problems with aluminum honeycomb panels. The honeycomb core absorbs and dissipates vibrational energy. You protect sensitive products during transportation because the panels prevent vibrations from reaching them. In industrial settings, you keep machines running smoothly. The panels act as natural vibration absorbers, which helps you extend the life of equipment and improve safety.

You use these panels in vehicles to make rides quieter and more comfortable.

You rely on them in factories to reduce wear and tear on machines.

You notice fewer breakdowns and less maintenance because vibrations do not damage components.

Aluminum honeycomb panels give you a reliable solution for vibration control in many applications. You improve comfort, safety, and performance with every installation.

You gain peace of mind when you choose aluminum honeycomb panels for fire safety. These panels use a non-combustible aluminum core, which means they do not burn or release toxic gases during a fire. You protect your building and its occupants with materials that meet strict global standards. Many high-rise buildings and commercial complexes require panels with the highest fire resistance rating. Aluminum honeycomb panels achieve the FR A1 classification, which is the top rating for fire safety.

Here is a table that shows how aluminum honeycomb panels perform in fire resistance:

| Feature | FR A1 Honeycomb Panels |

|---|---|

| Fire Resistance Rating | FR A1 (highest classification) |

| Non-combustibility | Yes |

| Smoke & Toxic Gas Emissions | Zero |

| Compliance with Global Standards | Yes |

| Suitable for High-Risk Environments | Yes (e.g., high-rise buildings, commercial complexes) |

You see the benefits in many applications. You use these panels in places where fire safety is critical, such as schools, hospitals, and transportation hubs. The panels do not contribute to the spread of flames. You also avoid the risk of harmful smoke or toxic gases, which can be dangerous during emergencies. When you select aluminum honeycomb panels, you meet building codes and safety regulations with confidence.

Tip: Always check the fire resistance rating before installing panels in high-risk environments. FR A1 panels offer the best protection.

You make a smart choice for safety and compliance when you use aluminum honeycomb panels. Their fire-resistant properties help you create secure spaces for everyone.

You support the environment when you choose aluminum honeycomb panels. These panels are fully recyclable, with a recycling rate of 100%. You help conserve resources and reduce waste by using materials that can be reused again and again. The recycling process for aluminum uses 95% less energy than producing new aluminum from raw materials. You lower your project's carbon footprint and save energy at the same time.

Aluminum stands out as one of the most sustainable materials available. About 75% of all aluminum produced in the last century is still in use today. You contribute to this cycle of reuse when you select aluminum honeycomb panels for your building or industrial project. Recycling aluminum also reduces greenhouse gas emissions, which helps fight climate change.

You see the difference when you compare aluminum honeycomb panels to non-recyclable alternatives. Other materials often require more energy to produce and create more pollution. You make a responsible choice for the planet by choosing panels that support sustainability.

♻️ 100% recyclable material

95% energy savings during recycling

Lower greenhouse gas emissions

You help build a better future with every panel you use. Aluminum honeycomb panels from Zhejiang Kangzhan New Materials Co. Ltd. give you the strength and durability you need, while also protecting the environment for generations to come.

When you choose materials for your project, you want to know how aluminum honeycomb panels stack up against other options. Let’s look at how they compare to composite panels, FRP panels, and solid aluminum.

Aluminum composite panels use a core made from materials like polyethylene (PE), fire-rated (FR) compounds, or minerals. You often see these panels in signage, interior walls, and low-load facades. Aluminum honeycomb panels, on the other hand, use a hollow aluminum core. This design makes them even lighter and much more rigid.

| Feature | Aluminum Composite Panel | Aluminum Honeycomb Panel |

|---|---|---|

| Core Material | PE, FR, or Mineral Core | Aluminum honeycomb |

| Weight | Lightweight | Even lighter due to hollow core |

| Rigidity | Moderate | High |

| Fire Resistance | Depends on core grade | Naturally fire-resistant |

| Cost | Lower | Higher |

| Use Case | Signage, interior, low-load | High-end facades, transport, ceilings |

You get higher strength and better fire resistance with honeycomb panels. They also provide excellent acoustic insulation. If your project needs a panel that is both strong and light, aluminum honeycomb panels give you a clear advantage. You may pay more, but you gain performance and safety.

Tip: Choose honeycomb panels for high-end facades or transportation projects where weight and strength matter most.

FRP (Fiber Reinforced Plastic) panels are another alternative. These panels are heavier because they use thicker layers of plastic. You find FRP panels in facades, signage, and furniture. Aluminum honeycomb panels weigh less and offer better formability. You can use them for flat or double-curved surfaces, which gives you more design freedom.

| Feature | FRP Panels (Composite) | Honeycomb Panels |

|---|---|---|

| Weight | Heavier due to thick plastic layers | Lighter with low-density core |

| Strength | Good rigidity and strength | High structural stability |

| Formability | Limited to flat/slightly curved | Can be double curved or flat |

| Application | Facades, signage, furniture | Transport, aerospace, military |

You get more flexibility with honeycomb panels. They work well in transportation, aerospace, and military uses. You also benefit from their lighter weight, which makes installation easier and reduces overall load.

Solid aluminum panels seem strong, but they have some drawbacks over time. You may notice microcracks forming under repeated loads. Aluminum honeycomb panels prevent crack propagation, so they last longer. Their structure gives you better fatigue life and stability under heavy or long-term loads.

| Feature | Aluminum Honeycomb Panels | Solid Aluminum Panels |

|---|---|---|

| Crack Propagation | Prevents cracks, more durable | Microcracks can form over time |

| Fatigue Life | Improved due to honeycomb structure | Lower, cracks form with stress |

| Stability under Load | High geometric stability, no creep | Can deform under long-term loads |

| Environmental Protection | Skins protect the core | No extra protection |

You also get extra protection from the upper and lower aluminum skins in honeycomb panels. These skins shield the core from the environment, which helps your panels last longer. If you want a panel that stays flat and strong for years, aluminum honeycomb panels give you a clear edge.

️ Note: For projects that demand long-term durability and stability, honeycomb panels outperform solid aluminum.

You can choose from a wide range of thickness options when selecting aluminum honeycomb panels. The thickness of each layer and the overall panel affects how the panel performs in different situations. Thicker panels give you more strength and durability, while thinner panels help you save weight and cost. The top and bottom aluminum sheets can also have different thicknesses, which lets you match the panel to your specific needs.

Here is a table that shows common thickness options and their impact on performance:

| Thickness Option | Impact on Performance |

|---|---|

| 0.8mm - 1.5mm (Top Sheet) | Greater strength, durability, and impact resistance |

| 0.6mm - 1.0mm (Bottom Sheet) | Adequate for lower stress applications |

| 5mm - 100mm (Panel Thickness) | Varies based on application needs |

| Up to 200mm (Panel Thickness) | Customizable for specific requirements |

You might use a thicker top sheet if you need extra protection against impacts or heavy loads. For less demanding uses, a thinner bottom sheet works well and helps keep the panel light. The total panel thickness can range from just a few millimeters up to 200mm, so you can always find the right fit for your project. If you need a custom size, Zhejiang Kangzhan New Materials Co. Ltd. can provide panels tailored to your requirements.

Tip: Thicker panels are best for areas that need more support or face higher stress, such as floors or exterior cladding.

You have several choices when it comes to the aluminum alloys used in honeycomb panels. The outer skins often use alloys like 5005 or 6063. These alloys offer good corrosion resistance and strength, making them suitable for outdoor and indoor applications. The honeycomb core usually uses alloys such as 3003 or 3005. These core alloys provide a balance between lightness and strength, which helps the panel stay rigid without adding unnecessary weight.

5005 Alloy: Good for facades and cladding because it resists corrosion.

6063 Alloy: Works well for architectural details and decorative finishes.

3003/3005 Alloy (Core): Delivers a strong yet lightweight core for most uses.

You can select the alloy type based on where you plan to use the panel. If you need extra protection against weather, choose a corrosion-resistant alloy. For interior spaces, you might focus more on appearance and finish.

The size of the honeycomb cells inside the panel plays a big role in how the panel performs. Smaller core cell sizes, especially when combined with higher densities, make the panel stronger and more resistant to impacts. This gives you a better strength-to-weight ratio, which is important if you want to keep things light but still need high performance.

You will find that panels with small cell sizes work best in demanding industries like aerospace, automotive, and architecture. These fields require materials that are both strong and lightweight. By choosing the right core cell size, you can improve efficiency and get the best results for your project.

Choosing the right combination of thickness, alloy, and core cell size ensures your aluminum honeycomb panel meets your exact needs.

When you select aluminum honeycomb panels, you need to consider the thickness of the aluminum foil used in the honeycomb core. Foil thickness plays a key role in the panel’s strength, durability, and overall performance. You can choose from a range of foil thicknesses to match your project’s requirements.

The foil thickness in aluminum honeycomb panels usually ranges from 0.1 mm to 3.0 mm. Thinner foils create lighter panels, which work well for applications where weight matters most, such as in transportation or aerospace. Thicker foils increase the panel’s tensile strength and resistance to impact, making them suitable for heavy-duty industrial or architectural uses.

Here is a table that shows common foil thickness ranges and how they affect performance:

| Foil Thickness Range | Performance Impact |

|---|---|

| 0.1 mm – 3.0 mm | Affects tensile strength and overall performance (50–200 MPa) |

You can also find specific foil thickness options, such as 0.1 mm and 0.18 mm, which are popular for lightweight panels. For projects that need extra strength, you might select thicker foils. The right choice depends on the balance you want between weight and durability.

Tip: Thicker foil increases the panel’s ability to handle stress and impact. Thinner foil keeps the panel light and easy to install.

You may see foil thickness listed in both millimeters and inches. Here are some common options you might encounter:

| Foil Thickness Options |

|---|

| 0.125" |

| 0.25" |

| 0.375" |

| 0.5" |

| 0.625" |

| 0.75" |

| 1" |

You should match the foil thickness to your application. For example, if you need panels for elevator interiors or cleanrooms, thinner foil may be enough. If you plan to use panels for machine surfaces or exterior cladding, thicker foil will give you better performance and longer service life.

Lightweight Applications: Choose thinner foil for easy handling and installation.

Heavy-Duty Applications: Select thicker foil for maximum strength and durability.

Custom Projects: Ask your supplier about custom foil thicknesses to meet unique needs.

You gain control over your project’s outcome by understanding foil thickness. When you work with Zhejiang Kangzhan New Materials Co. Ltd., you can select the ideal foil thickness for your aluminum honeycomb panels. This ensures you get the right balance of weight, strength, and performance every time.

You make a smart choice for the planet when you select aluminum honeycomb panels. These panels support sustainability goals in construction and industry. Aluminum can be recycled many times without losing its strength or quality. You help create a circular economy because recycled aluminum retains its physical and chemical properties. This means you can reuse it again and again.

Aluminum honeycomb panels contribute to green building certifications like LEED.

You reduce waste and energy consumption by choosing recyclable materials.

Aluminum keeps its quality after recycling, so you do not sacrifice performance.

You support sustainable construction because aluminum can be recycled without limit.

You see the benefits in every stage of a building’s life. When you use panels with recycled skins, you lower environmental impacts across all categories. You help reduce global warming potential, material depletion, and ozone depletion. If you choose natural flax fibers for the skins, you can cut most environmental impact indicators by 78%. However, you should know that this increases land use and toxicity because of farming needs.

Here is a table showing how different panel choices affect environmental indicators:

| Panel Type | GWP Reduction | MDP Reduction | ODP Reduction | Land Use | Toxicity |

|---|---|---|---|---|---|

| Recycled Aluminum Skins | ✔️ | ✔️ | ✔️ | — | — |

| Natural Flax Fiber Skins | 78% | 78% | 78% | ↑ | ↑ |

| Biopolymer Sandwich | ✔️ | — | — | — | ↑ |

♻️ Tip: You help the environment every time you choose panels made from recycled aluminum.

You improve energy efficiency in your building when you use aluminum honeycomb panels. The honeycomb structure provides excellent thermal insulation. You notice that your building stays cooler in summer and warmer in winter. This design reduces the need for frequent air-conditioning adjustments. You save energy and lower your utility bills.

Aluminum honeycomb panels help you create comfortable indoor spaces. You see less heat transfer between rooms and the outdoors. This means you use less energy for heating and cooling. Buildings with these panels often meet strict energy standards and perform better in both hot and cold climates.

You reduce energy consumption by improving insulation.

You lower energy costs for your building.

You support green building goals with better thermal performance.

You also help the environment by using less energy. Lower energy use means fewer greenhouse gas emissions. You make your building more sustainable and cost-effective. When you choose aluminum honeycomb panels, you invest in a future where buildings use resources wisely.

Note: Good insulation does more than save money. It helps protect the planet by reducing energy demand.

You can choose aluminum honeycomb panels in custom sizes to fit your project needs. This flexibility helps you solve challenges in construction, transportation, and industrial design. You select the core thickness, panel skin material, and coating type. You get panels that match your exact requirements.

Manufacturers use advanced processing methods like CNC cutting, bending, and hot pressing. These techniques allow you to order panels in almost any shape or size. You receive prototypes quickly, sometimes within seven days. You also get engineering support, including help with technical drawings and material selection. This support makes your design process easier and more efficient.

Here is a table showing how custom options meet different needs:

| Feature | Description |

|---|---|

| Custom options | Core thickness, panel skin material, coating types. |

| Flexible processing | CNC cutting, bending, bonding, hot pressing. |

| Surface finishes | PVDF coating, anodizing, wood grain, stone texture. |

| Fast delivery | Prototype completed within 7 days. |

| Tailored Engineering Support | Technical drawing assistance, material selection guidance, custom design optimization. |

| Advanced Manufacturing | Precision CNC, hot-press bonding, and automated coating lines. |

| Reliable Lead Times | Samples can be ready in as fast as 7 days. |

| Certified Quality Assurance | ISO-certified processes and rigorous in-house testing. |

You benefit from reliable lead times and certified quality assurance. You know your panels will meet strict standards and arrive on schedule. This flexibility lets you create unique designs for facades, ceilings, vehicles, and machines.

Tip: Custom sizing helps you avoid waste and reduces installation time. You get panels that fit perfectly, saving you money and effort.

You have many choices for surface finishes on aluminum honeycomb panels. These finishes affect both durability and appearance. You select a finish based on your project’s environment and style.

Anodized finishes give you long-lasting durability. They resist weather and wear, and you can pick from many colors and textures. Powder-coated panels offer strong adhesion and protect against chipping, scratching, and fading. You get a tough surface that stands up to harsh conditions. Painted finishes allow for high customization with many colors, but they need more maintenance because they can chip or fade. Mill finish panels cost less and have a simple, smooth metallic look, but they are more likely to corrode.

Here is a table that compares surface finishes:

| Surface Finish | Durability Impact | Aesthetic Impact |

|---|---|---|

| Anodized | Long-lasting durability, resistant to environmental factors. | Offers a wide range of colors and textures. |

| Powder-coated | Excellent adhesion and durability, resistant to chipping, scratching, and fading. | Provides a strong bond and good corrosion protection. |

| Painted | Prone to chipping and fading, requires more maintenance. | High degree of customization with various colors. |

| Mill Finish | Cost-effective but more susceptible to corrosion. | Simple, industrial look with a smooth metallic finish. |

You match the finish to your project’s needs. For outdoor facades, you might choose anodized or powder-coated panels for extra protection. For interior spaces, painted panels let you create bold designs. Mill finish works well in industrial settings where cost matters most.

️ Note: The right surface finish improves both the lifespan and the look of your aluminum honeycomb panels. You get panels that perform well and look great in any setting.

You face several manufacturing challenges when working with aluminum honeycomb panels. The process requires precision and advanced technology. You need to bond thin aluminum skins to a honeycomb core without defects. This step demands skilled labor and specialized equipment. You also must meet strict standards for fire safety and structural performance.

Leading companies address these challenges by investing in innovation. They use automated production lines and advanced bonding techniques. You see a focus on sustainability, with manufacturers training workers to handle specialized fabrication and installation. Collaboration with suppliers helps maintain a stable supply of high-quality aluminum. Companies streamline their processes to comply with regulations and environmental standards.

Here is a table that shows common manufacturing challenges and solutions:

| Challenge | Solution |

|---|---|

| High initial costs | Innovation and investment in advanced manufacturing techniques |

| Specialized fabrication and installation | Focus on sustainability and skilled labor training |

| Supply chain disruptions | Collaboration with suppliers to ensure stability in aluminum procurement |

| Regulatory compliance | Streamlining processes to meet fire safety, structural performance, and environmental standards |

Note: You benefit from these improvements because they lead to higher quality panels and more reliable delivery times.

You notice that aluminum honeycomb panels often cost more than traditional materials. The manufacturing process uses advanced machinery and skilled labor. You pay for the precision and durability that these panels offer. The initial investment may seem high, but you gain long-term savings through reduced maintenance and longer service life.

You also save money on installation. The lightweight nature of the panels means you need less labor and equipment. You reduce transportation costs because the panels weigh less than solid aluminum sheets. Over time, you see lower energy bills due to the insulation properties of the honeycomb structure.

You invest more upfront, but you save on maintenance and energy.

You spend less on transportation and installation.

You benefit from the durability and long lifespan of the panels.

Tip: Consider the total cost of ownership, not just the purchase price. Aluminum honeycomb panels often provide better value over time.

You find that aluminum honeycomb panels excel in many areas, but they have some limits. You use them for facades, ceilings, cleanrooms, and transportation, but some applications require different materials. For example, you may need panels with extra thickness or specific finishes for unique environments.

You must consider the design and engineering requirements of your project. Some shapes or sizes may need custom manufacturing. You work with suppliers to ensure the panels meet your specifications. You also check compatibility with other building materials and systems.

You select panels based on project needs and technical requirements.

You consult with manufacturers for custom solutions.

You verify that the panels fit your design and performance goals.

Remember: Aluminum honeycomb panels offer flexibility, but you should always match the product to your specific application for the best results.

You see how aluminum honeycomb panels offer strength, lightness, and sustainability for many industries. You can use them in buildings, vehicles, and cleanrooms. You get reliable performance and easy installation. If you want advanced solutions, Zhejiang Kangzhan New Materials Co. Ltd. gives you innovative products. You will notice new uses and better technology as the industry grows.

Strong and lightweight for many projects

Sustainable choice for the future

Ongoing innovation expands possibilities

You get a lightweight panel with a honeycomb core. This design gives you more strength and better insulation than a solid aluminum sheet. You also see improved fire resistance and flatness.

You can use these panels outdoors. They resist corrosion and weather. You often see them on building facades, sun shades, and exterior cladding. You choose finishes like anodizing or powder coating for extra protection.

You clean panels with mild soap and water. You use a soft cloth or sponge. Avoid harsh chemicals. You keep surfaces smooth and hygienic, especially in cleanrooms or medical spaces.

Tip: Regular cleaning helps maintain the panel’s appearance and performance.

You choose aluminum honeycomb panels for fire safety. The non-combustible core does not burn or release toxic gases. You meet strict building codes in schools, hospitals, and high-rise buildings.

You select custom sizes and thicknesses. Panels range from 5mm to 200mm thick. You match the panel to your project’s needs. Zhejiang Kangzhan New Materials Co. Ltd. offers tailored solutions.

| Thickness Range | Common Uses |

|---|---|

| 5–20 mm | Ceilings, interiors |

| 20–100 mm | Facades, machines |

| 100–200 mm | Special projects |

You recycle these panels completely. Aluminum keeps its quality after recycling. You help the environment and support green building goals.

♻️ Recycling aluminum saves energy and reduces waste.